April 18th, 2012

When one needs to buy the mills, they need to find out some of the manufacturers and the importers of the different brands. One needs to know the feed pellet mill Wholesalers and the different brands that they are selling. In the recent past, there have been different manufacturers of the mill pellets and some of them are not dealing with the legit brands. Some of them make the cheaper brands and when used for a few months, they start to slow down and eventually break down. Others do not have the spare parts since they are new in the market and this makes it hard for one to get the parts and the mill to work as desired.

When one needs to buy the mills, they need to find out some of the manufacturers and the importers of the different brands. One needs to know the feed pellet mill Wholesalers and the different brands that they are selling. In the recent past, there have been different manufacturers of the mill pellets and some of them are not dealing with the legit brands. Some of them make the cheaper brands and when used for a few months, they start to slow down and eventually break down. Others do not have the spare parts since they are new in the market and this makes it hard for one to get the parts and the mill to work as desired.

Some people on the other hand do not know where to get the ideal and reliable feed pellet mill Wholesalers. Some have made the business big by training on the different areas to repair the mills and sell the spare parts. It is common for the machines to break down but one needs to have the backup when needed. Another function of the wholesaler is to stock the reliable brands in the store and serve the clients when they are in need. They deal with advising the client on some of the best brands, conduct research to find the latest brands and import the mills on behalf of the clients and get them the high quality brands.

Categories: Feed Pellet Mill Wholesalers |

Comments Off

April 17th, 2012

Some people have direct links to the feed pellet mill Importers and have the chance to get access to some of the greatest pellet mils at affordable prices. Some have gone as far as starting very reputable businesses when it comes to the sale of the mills especially to the independent owners and ranch owners who find it appropriate to use the mills to grind the feeds of the animals. One of the aspects to keep in mind is the ability to have the mill to grind from the ranch and this will cut on the costs of going to the millers or hiring the independent millers to come to the ranch. Considering this is done of an daily basis, one gets to spend loads of cash on the milers and it is hence much cheaper to have the mill on the ranch

Some people have direct links to the feed pellet mill Importers and have the chance to get access to some of the greatest pellet mils at affordable prices. Some have gone as far as starting very reputable businesses when it comes to the sale of the mills especially to the independent owners and ranch owners who find it appropriate to use the mills to grind the feeds of the animals. One of the aspects to keep in mind is the ability to have the mill to grind from the ranch and this will cut on the costs of going to the millers or hiring the independent millers to come to the ranch. Considering this is done of an daily basis, one gets to spend loads of cash on the milers and it is hence much cheaper to have the mill on the ranch

With access to the feed pellet mill Importers, one gets to find the different types of mills, check on the quality of the brand, the size of the pellets they produce, and the way they operate. Some people prefer to give some of the large mills since they have a large ranch and need to make the pellets faster to save on the storage space. The work of the importers is to ensure that the client gets the mill they want, the right price and functioning well. One needs to know the manufacturer, check on the reviews, and find out the different testimonies from other people.

Categories: Feed Pellet Mill |

Comments Off

April 16th, 2012

The feed pellet mill Manufacturers have perfected the art of making the mills, and suitable for processing the feeds of the animals into fine pellets. Some of the companies have taken the time to come with various sizes of the pellets since some animals prefer them when large and others prefer them when small. The little animals need it smaller foods as opposed to the large animals. One of the places to get the manufactures is through conducting research online, or uses the directories and newspapers.

The feed pellet mill Manufacturers have perfected the art of making the mills, and suitable for processing the feeds of the animals into fine pellets. Some of the companies have taken the time to come with various sizes of the pellets since some animals prefer them when large and others prefer them when small. The little animals need it smaller foods as opposed to the large animals. One of the places to get the manufactures is through conducting research online, or uses the directories and newspapers.

When one gets in touch with the animals feeds industry, they get to find out more on the feed pellet mill Manufacturers and find the different players in the market. Some of them take time to create the mills run by electricity and they are fast, reliable, and quite effective. Some of them deal with the mobile mills and this is good for the people who want to conduct the business and find it applicable to move from one location to another. Some of them use the solar technique and this is environmental friendly and saves on the costs of operation. It is advisable to find some of the reliable and reputable manufactures in this industry through using the online resources to get the reviews and asking people on the different types of mills that are ideal for business or for personal use. Through research, one gets to rely on the best manufacturers of the feed mills in the industry.

Categories: Feed Pellet Mill |

Comments Off

March 10th, 2012

Finding an ideal pellet mill for your needs can be a daunting task. There are so many brands and models in the market that it can sometimes leave you with too many options to choose from. Variety is not always a benefit for a consumer as you might have realized in the past. With these many models, you can never know which one to choose or which one will fit your needs. But there are some insider tips you can use to land the perfect mill when you are searching for a pellet mill for sale. These tips are used by some of the largest millers in the world. SO if they worked for them, they should also work for you.

Moving on swiftly, the first and perhaps most important consideration you should have when it comes to purchasing a pellet mill is your budget allocation. Have an exact idea on the amount of money you want to invest in a pellet mill. This should narrow things a bit since you will skip right to the price bracket that best fits you. You should never hunt for a pellet mill for sale without having an idea as to the kind of money you are willing to spend.

Moving on swiftly, the first and perhaps most important consideration you should have when it comes to purchasing a pellet mill is your budget allocation. Have an exact idea on the amount of money you want to invest in a pellet mill. This should narrow things a bit since you will skip right to the price bracket that best fits you. You should never hunt for a pellet mill for sale without having an idea as to the kind of money you are willing to spend.

Next you will have to consider the ‘why’ of buying a pellet mill. What purpose is your mill going to serve? Will it be a commercial mill or will it be used domestically. Answering this question will also arrow things down a bit. You will be left with either heavy duty mills or small mills categories to rummage through. You can then read reviews on the brands you came across and with this you should locate the perfect pellet mill for sale to fit all your needs.

Categories: Feed Pellet Mill |

Comments Off

March 9th, 2012

There are different types of feed pellet recipes today and all you have to do is to recognize yourself with the type that is suitable for your needs and preferences. Remember, it makes no sense for you to choose a feed pellet recipe that you know will; not work effectively for you. It is important to know that the nutrition in the feed pellets is considered to be very high compared to others. In addition to this, it is important to as well know that feed pellet recipes are very clear and simple compared to other complicated formula recipes that are easily floating on the internet.

There are different types of feed pellet recipes today and all you have to do is to recognize yourself with the type that is suitable for your needs and preferences. Remember, it makes no sense for you to choose a feed pellet recipe that you know will; not work effectively for you. It is important to know that the nutrition in the feed pellets is considered to be very high compared to others. In addition to this, it is important to as well know that feed pellet recipes are very clear and simple compared to other complicated formula recipes that are easily floating on the internet.

For you to be able to use these recipes effectively, it is important to follow the directions that have been provided by the manufacturer. On each feed pellet recipe, you are provided with directions on what you are supposed to do in order to achieve the best results. Feed pellets are very important and as such, it is important to use the right recipe to come up with them. The feed pellets can either be made for animals such as horses, chickens and cows. Identify with the needs of your animals in order to choose the right recipe.

Categories: Feed Pellet Recipes |

Comments Off

March 8th, 2012

Feed Pellet Mill Company is well renowned for its prowess in designing and manufacturing the best feed pelletizer machines. The company has been in the industry for a long period of time and this has helped it to gain more experience in designing and manufacturing the latest machines. As this is not enough, the company has qualified manufacturers who are ready and willing to ensure all the needs and preferences of the customers are well taken care of.

Feed Pellet Mill Company is well renowned for its prowess in designing and manufacturing the best feed pelletizer machines. The company has been in the industry for a long period of time and this has helped it to gain more experience in designing and manufacturing the latest machines. As this is not enough, the company has qualified manufacturers who are ready and willing to ensure all the needs and preferences of the customers are well taken care of.

The best thing about feed pelletizer machines designed by this company is that they are all of quality standards which means that if anything goes haywire, you have a right to make your claim as soon as you can. The company is highly reputed and this has helped it increase its sales with a big margin. The company has used this money to ensure that all the machines are designed with the latest technology to match the needs of their customers’ best. The machines come in different sizes, shapes, designs and prices and as such, you have a chance of choosing the machine that will work for your needs effectively. The company is available on 24/7 which means that you can contact it anytime for any service you want.

Categories: Feed Pelletizer Machines |

Comments Off

March 7th, 2012

The prices of pellet mills go hand in hand with the special use of these machines. Also the manufactures determine the prices for the machine. For example a HKJ508 Wood Pellet Mill cost as much as 40000 – 50000 US Dollars. While others go for 1600 – 3000 US Dollars.

A person may buy according to their preference and what they want to use it for. Home use biomass pellet mill for wood and feed pellet will even go as low as US $520 which has a capacity to take up to 75-100kg/h. if you are looking for a pellet mill for wood sawdust, rice husk, cotton stalk, cotton skins ,weeds etc, you can also have it for US $800 – 2000 a set.

A person may buy according to their preference and what they want to use it for. Home use biomass pellet mill for wood and feed pellet will even go as low as US $520 which has a capacity to take up to 75-100kg/h. if you are looking for a pellet mill for wood sawdust, rice husk, cotton stalk, cotton skins ,weeds etc, you can also have it for US $800 – 2000 a set.

Some manufacturers have even come up with high efficiency pellet mill with cost effective prices. They will serve you with long life, high efficiency, and also save energy

Categories: Feed Pellet Mill |

Comments Off

March 6th, 2012

Finding a quality feed pellet mill is not as easy as you might think. There are very few good companies out there manufacturing quality pellet mills. You need a company that will not only supply you with a durable mill but also a mill that can be serviced, a mill that you can get spare parts for as well as a pellet mill that will perform according to your expectations. But finding such a company can be a tricky due to the wide spectrum of pellet mill supplies. However it comes as welcome surprise that people, especially consumers have taken the liberty to list some of the good pellet mill manufacturers and feed pellet mill India supplies come highly recommended in this list. Feed pellet mills from India have the uncanny ability to deliver constant output for long periods of time. These mills are the preferred choice of many industrial organizations specializing in pellet production.

Finding a quality feed pellet mill is not as easy as you might think. There are very few good companies out there manufacturing quality pellet mills. You need a company that will not only supply you with a durable mill but also a mill that can be serviced, a mill that you can get spare parts for as well as a pellet mill that will perform according to your expectations. But finding such a company can be a tricky due to the wide spectrum of pellet mill supplies. However it comes as welcome surprise that people, especially consumers have taken the liberty to list some of the good pellet mill manufacturers and feed pellet mill India supplies come highly recommended in this list. Feed pellet mills from India have the uncanny ability to deliver constant output for long periods of time. These mills are the preferred choice of many industrial organizations specializing in pellet production.

Another feature that draws people to pellet mills from India is the fact that they are easy to maintain. The mills tend not to have many moving parts which reduces the chances of something going wrong and also it reduces the costs of repairs should they become necessary.

Categories: Feed Pellet Mill |

Comments Off

March 5th, 2012

The standard-setting organization, the Global Aquaculture Alliance, recently completed the BAP references for feed mill aquaculture certification. Apart from linking to the best aquaculture practices certification, the move allows the feed manufacturers to subscribe to BAP certification as well. The standards provide for expanded BAP certification to include complete aquaculture chain production. This encompasses hatchery and all the way up to the processing machinery. Feed manufacturers can now contact Best Aquaculture Practices Certification Management on issues related to BAP certification. The standards do address food safety while undergoing through the processing stage as well as long term sustainability of fishmeal sources.

The standard-setting organization, the Global Aquaculture Alliance, recently completed the BAP references for feed mill aquaculture certification. Apart from linking to the best aquaculture practices certification, the move allows the feed manufacturers to subscribe to BAP certification as well. The standards provide for expanded BAP certification to include complete aquaculture chain production. This encompasses hatchery and all the way up to the processing machinery. Feed manufacturers can now contact Best Aquaculture Practices Certification Management on issues related to BAP certification. The standards do address food safety while undergoing through the processing stage as well as long term sustainability of fishmeal sources.

The program (BAP) demands that farmers develop viable plans that will not lead to unstable sources of raw material. Well managed fisheries should be able to transit from fishmeal to fish oil undertakings. Projected target aim to derive fishmeal byproducts from certified fisheries of up to 50 percent in the coming five years. Certified feed mill aquaculture must thus show an indication of fish inclusion factor on all product tags, packaging including any other documentation that justifies marine ingredient component for all the aquaculture feeds. This helps facilitate easy tabulation of input and output of fish ratios. Development of standards governing aquaculture feed mills involve stake holder from mainstream ingredient suppliers, manufacturers including NGOs. The standards not only help to address food safety but environmental responsibility as well.

The program (BAP) demands that farmers develop viable plans that will not lead to unstable sources of raw material. Well managed fisheries should be able to transit from fishmeal to fish oil undertakings. Projected target aim to derive fishmeal byproducts from certified fisheries of up to 50 percent in the coming five years. Certified feed mill aquaculture must thus show an indication of fish inclusion factor on all product tags, packaging including any other documentation that justifies marine ingredient component for all the aquaculture feeds. This helps facilitate easy tabulation of input and output of fish ratios. Development of standards governing aquaculture feed mills involve stake holder from mainstream ingredient suppliers, manufacturers including NGOs. The standards not only help to address food safety but environmental responsibility as well.

Categories: Feed Mill Aquaculture |

Comments Off

March 3rd, 2012

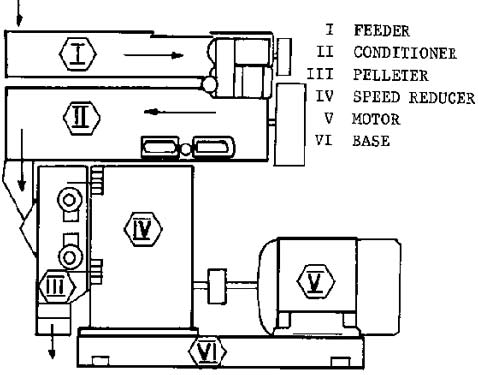

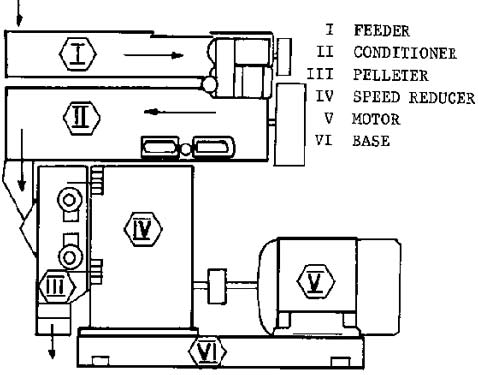

There are three basic differences when it comes to feed mill equipment as well as other associated accessories required in the production of pellets. In majority of equipment, the first in priority is the hammer mill which works on the attrition and frequency of hammers. It provides necessary impact to crush raw materials reducing them into small equal sizes. Typical sizes are barely in millimeter dimensions.

Your desired size of pellets determines the amount of particles coming out of your equipment. In general, particles must be smaller compared to the pellets produced. For instance if you desire to produce 6mm diameter of pellets, then choose particles with less diameter for your machine. It suffices to note that pellet making machines with a circular die component is specially designed to produce animal feed pellets. This particular type of feed mill equipment is characterized by low power consumption with more output.

Your desired size of pellets determines the amount of particles coming out of your equipment. In general, particles must be smaller compared to the pellets produced. For instance if you desire to produce 6mm diameter of pellets, then choose particles with less diameter for your machine. It suffices to note that pellet making machines with a circular die component is specially designed to produce animal feed pellets. This particular type of feed mill equipment is characterized by low power consumption with more output.

Feed ingredients obtained from corn are mostly viscous and easily shaped. It requires optimum pressure to generate trip. As for wood chips, meal and discarded tires including heat resistant materials require a lot of pressure. Due to its design limitations, ring pellet feed mill equipment do not provide for adjustable parts as it will crush the materials beyond pressure loads resulting in wear and tear of roller bearing.

Categories: Feed Mill Equipment |

Comments Off

Some people have direct links to the feed pellet mill Importers and have the chance to get access to some of the greatest pellet mils at affordable prices. Some have gone as far as starting very reputable businesses when it comes to the sale of the mills especially to the independent owners and ranch owners who find it appropriate to use the mills to grind the feeds of the animals. One of the aspects to keep in mind is the ability to have the mill to grind from the ranch and this will cut on the costs of going to the millers or hiring the independent millers to come to the ranch. Considering this is done of an daily basis, one gets to spend loads of cash on the milers and it is hence much cheaper to have the mill on the ranch

Some people have direct links to the feed pellet mill Importers and have the chance to get access to some of the greatest pellet mils at affordable prices. Some have gone as far as starting very reputable businesses when it comes to the sale of the mills especially to the independent owners and ranch owners who find it appropriate to use the mills to grind the feeds of the animals. One of the aspects to keep in mind is the ability to have the mill to grind from the ranch and this will cut on the costs of going to the millers or hiring the independent millers to come to the ranch. Considering this is done of an daily basis, one gets to spend loads of cash on the milers and it is hence much cheaper to have the mill on the ranch The feed pellet mill Manufacturers have perfected the art of making the mills, and suitable for processing the feeds of the animals into fine pellets. Some of the companies have taken the time to come with various sizes of the pellets since some animals prefer them when large and others prefer them when small. The little animals need it smaller foods as opposed to the large animals. One of the places to get the manufactures is through conducting research online, or uses the directories and newspapers.

The feed pellet mill Manufacturers have perfected the art of making the mills, and suitable for processing the feeds of the animals into fine pellets. Some of the companies have taken the time to come with various sizes of the pellets since some animals prefer them when large and others prefer them when small. The little animals need it smaller foods as opposed to the large animals. One of the places to get the manufactures is through conducting research online, or uses the directories and newspapers. Moving on swiftly, the first and perhaps most important consideration you should have when it comes to purchasing a pellet mill is your budget allocation. Have an exact idea on the amount of money you want to invest in a pellet mill. This should narrow things a bit since you will skip right to the price bracket that best fits you. You should never hunt for a pellet mill for sale without having an idea as to the kind of money you are willing to spend.

Moving on swiftly, the first and perhaps most important consideration you should have when it comes to purchasing a pellet mill is your budget allocation. Have an exact idea on the amount of money you want to invest in a pellet mill. This should narrow things a bit since you will skip right to the price bracket that best fits you. You should never hunt for a pellet mill for sale without having an idea as to the kind of money you are willing to spend. There are different types of feed pellet recipes today and all you have to do is to recognize yourself with the type that is suitable for your needs and preferences. Remember, it makes no sense for you to choose a feed pellet recipe that you know will; not work effectively for you. It is important to know that the nutrition in the feed pellets is considered to be very high compared to others. In addition to this, it is important to as well know that feed pellet recipes are very clear and simple compared to other complicated formula recipes that are easily floating on the internet.

There are different types of feed pellet recipes today and all you have to do is to recognize yourself with the type that is suitable for your needs and preferences. Remember, it makes no sense for you to choose a feed pellet recipe that you know will; not work effectively for you. It is important to know that the nutrition in the feed pellets is considered to be very high compared to others. In addition to this, it is important to as well know that feed pellet recipes are very clear and simple compared to other complicated formula recipes that are easily floating on the internet. Feed Pellet Mill Company is well renowned for its prowess in designing and manufacturing the best feed pelletizer machines. The company has been in the industry for a long period of time and this has helped it to gain more experience in designing and manufacturing the latest machines. As this is not enough, the company has qualified manufacturers who are ready and willing to ensure all the needs and preferences of the customers are well taken care of.

Feed Pellet Mill Company is well renowned for its prowess in designing and manufacturing the best feed pelletizer machines. The company has been in the industry for a long period of time and this has helped it to gain more experience in designing and manufacturing the latest machines. As this is not enough, the company has qualified manufacturers who are ready and willing to ensure all the needs and preferences of the customers are well taken care of.

A person may buy according to their preference and what they want to use it for. Home use biomass pellet mill for wood and feed pellet will even go as low as US $520 which has a capacity to take up to 75-100kg/h. if you are looking for a pellet mill for wood sawdust, rice husk, cotton stalk, cotton skins ,weeds etc, you can also have it for US $800 – 2000 a set.

A person may buy according to their preference and what they want to use it for. Home use biomass pellet mill for wood and feed pellet will even go as low as US $520 which has a capacity to take up to 75-100kg/h. if you are looking for a pellet mill for wood sawdust, rice husk, cotton stalk, cotton skins ,weeds etc, you can also have it for US $800 – 2000 a set. Finding a quality feed pellet mill is not as easy as you might think. There are very few good companies out there manufacturing quality pellet mills. You need a company that will not only supply you with a durable mill but also a mill that can be serviced, a mill that you can get spare parts for as well as a pellet mill that will perform according to your expectations. But finding such a company can be a tricky due to the wide spectrum of pellet mill supplies. However it comes as welcome surprise that people, especially consumers have taken the liberty to list some of the good pellet mill manufacturers and feed pellet mill India supplies come highly recommended in this list. Feed pellet mills from India have the uncanny ability to deliver constant output for long periods of time. These mills are the preferred choice of many industrial organizations specializing in pellet production.

Finding a quality feed pellet mill is not as easy as you might think. There are very few good companies out there manufacturing quality pellet mills. You need a company that will not only supply you with a durable mill but also a mill that can be serviced, a mill that you can get spare parts for as well as a pellet mill that will perform according to your expectations. But finding such a company can be a tricky due to the wide spectrum of pellet mill supplies. However it comes as welcome surprise that people, especially consumers have taken the liberty to list some of the good pellet mill manufacturers and feed pellet mill India supplies come highly recommended in this list. Feed pellet mills from India have the uncanny ability to deliver constant output for long periods of time. These mills are the preferred choice of many industrial organizations specializing in pellet production. The standard-setting organization, the Global Aquaculture Alliance, recently completed the BAP references for feed mill aquaculture certification. Apart from linking to the best aquaculture practices certification, the move allows the feed manufacturers to subscribe to BAP certification as well. The standards provide for expanded BAP certification to include complete aquaculture chain production. This encompasses hatchery and all the way up to the processing machinery. Feed manufacturers can now contact Best Aquaculture Practices Certification Management on issues related to BAP certification. The standards do address food safety while undergoing through the processing stage as well as long term sustainability of fishmeal sources.

The standard-setting organization, the Global Aquaculture Alliance, recently completed the BAP references for feed mill aquaculture certification. Apart from linking to the best aquaculture practices certification, the move allows the feed manufacturers to subscribe to BAP certification as well. The standards provide for expanded BAP certification to include complete aquaculture chain production. This encompasses hatchery and all the way up to the processing machinery. Feed manufacturers can now contact Best Aquaculture Practices Certification Management on issues related to BAP certification. The standards do address food safety while undergoing through the processing stage as well as long term sustainability of fishmeal sources. The program (BAP) demands that farmers develop viable plans that will not lead to unstable sources of raw material. Well managed fisheries should be able to transit from fishmeal to fish oil undertakings. Projected target aim to derive fishmeal byproducts from certified fisheries of up to 50 percent in the coming five years. Certified feed mill aquaculture must thus show an indication of fish inclusion factor on all product tags, packaging including any other documentation that justifies marine ingredient component for all the aquaculture feeds. This helps facilitate easy tabulation of input and output of fish ratios. Development of standards governing aquaculture feed mills involve stake holder from mainstream ingredient suppliers, manufacturers including NGOs. The standards not only help to address food safety but environmental responsibility as well.

The program (BAP) demands that farmers develop viable plans that will not lead to unstable sources of raw material. Well managed fisheries should be able to transit from fishmeal to fish oil undertakings. Projected target aim to derive fishmeal byproducts from certified fisheries of up to 50 percent in the coming five years. Certified feed mill aquaculture must thus show an indication of fish inclusion factor on all product tags, packaging including any other documentation that justifies marine ingredient component for all the aquaculture feeds. This helps facilitate easy tabulation of input and output of fish ratios. Development of standards governing aquaculture feed mills involve stake holder from mainstream ingredient suppliers, manufacturers including NGOs. The standards not only help to address food safety but environmental responsibility as well. Your desired size of pellets determines the amount of particles coming out of your equipment. In general, particles must be smaller compared to the pellets produced. For instance if you desire to produce 6mm diameter of pellets, then choose particles with less diameter for your machine. It suffices to note that pellet making machines with a circular die component is specially designed to produce animal feed pellets. This particular type of feed mill equipment is characterized by low power consumption with more output.

Your desired size of pellets determines the amount of particles coming out of your equipment. In general, particles must be smaller compared to the pellets produced. For instance if you desire to produce 6mm diameter of pellets, then choose particles with less diameter for your machine. It suffices to note that pellet making machines with a circular die component is specially designed to produce animal feed pellets. This particular type of feed mill equipment is characterized by low power consumption with more output.